About Micro Engineering, Inc.

A company that develops, manufactures, and sells manufacturing machine for semiconductors, FPDs, photomasks, etc.

Please rely on equipment related to the manufacturing of electronic materials.

We support the creation of an optimal production system for our customers.

Message from the President

Since our foundation, we have been manufacturing and selling manufacturing machine in the manufacturing process of electronic components and chemical products that support science and technology.

We always place great importance on the environment, and have a great deal of track record in responding quickly to the changes and demands of each era.

President & CEO Hajime Tomizawa

CHALLENGE

With the latest technology, we are taking on the challenge of creating new value in response to the changing times and demands.

-

Semiconductor

Fully Automatic CMP Machine (MGP808XJ)

Fully automatic CMP machines "MGP808XJ" is a successor model of "LGP-808XJ" made by the Lap Master SFT. We adapt new heads which we developed, and it has been achieved to improve GBIR and SFQR of wafer's surface which is increasing year by year.

Major Product Categories

-

Factory Automation

FOSB/FOUP Automatic Packaging Machine (MAP300)

The automatic packaging machine (MP300) transports the wafer cassette (FOSB) placed at the loading location (loader section) to the inspection area. In the inspection area, FOSB are inspected by conducting hosted communications. The inspection contents are FOSB type, confirmation of wafer position and inspection of the number of wafers. In the packaging area, one-or two-tier packaging is conducted. By automating the visual inspection and packaging work that was conventionally performed manually, it is possible to reduce human error, shorten the work time, and make the packaging quality uniform.

Major Product Categories

-

Inspection

Wafer defect inspection Machine

The wafer defect inspection machine (MICW300) takes out the wafer from the BOX which set by OHT or operator at the load port (FOSB opener) and inspects at each position.

Store OK products transfer to the original place and NG products transfer to the NG BOX.

In addition, automation from conventional visual inspection can reduce human error and save waste time.Major Product Categories

-

Healthcare

CIRCULA

Previous hand dryers used to spray and dry water droplets and dust into the air. CIRCULA has been developed as the only aspiration-type hand dryer in the country and prevents the dispersion of waterdrops, miscellaneous fungal, viruses, etc. by 99.7% compared to conventional ones. ※1

Compared to the conventional hand dryer whose temporary use was prohibited by COVID-19, CIRCULA is expected as a countermeasure against infectious diseases because it prevents the spread of viruses.※1:Comparison time at 40cm point above the discharge port of the hand dryer for 10 seconds

Major Product Categories

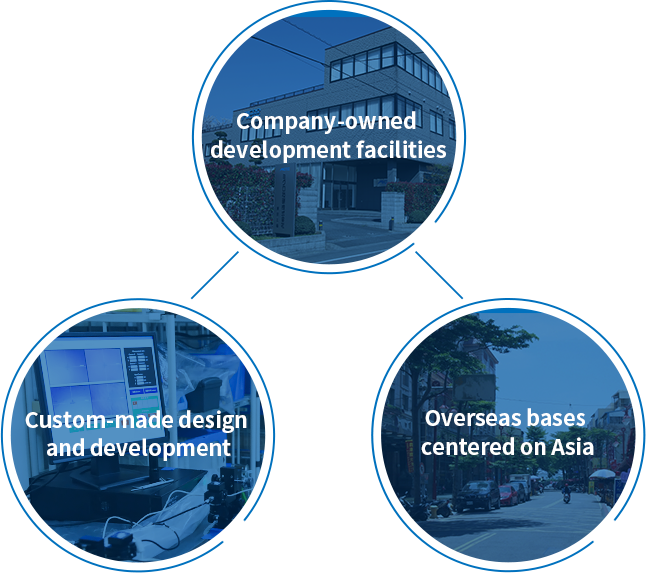

OUR STRENGTH

Our strengths at Micro Engineering, Inc.

-

Custom-made design and development

-

Company-owned development facilities

-

Overseas bases centered on Asia

Development Facilities

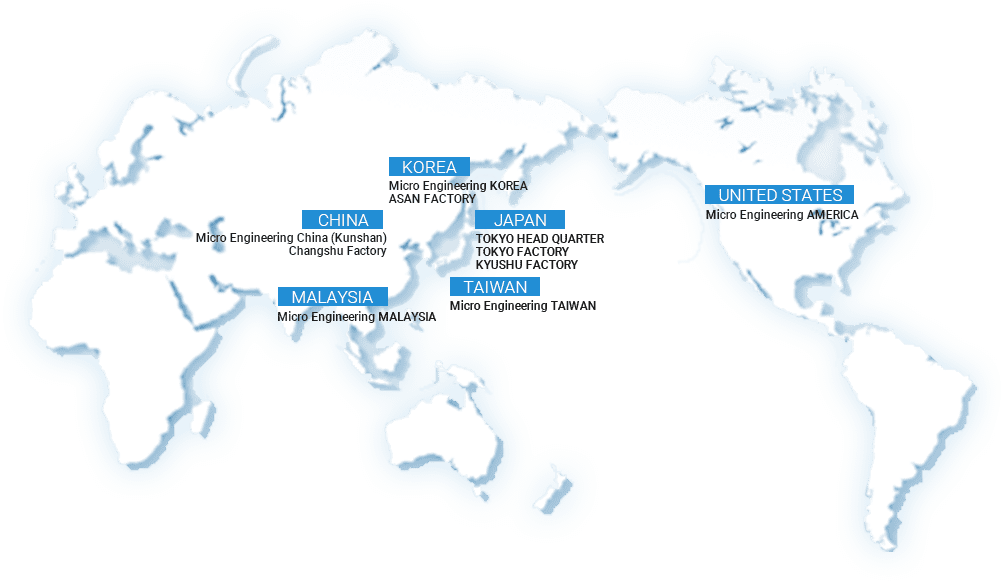

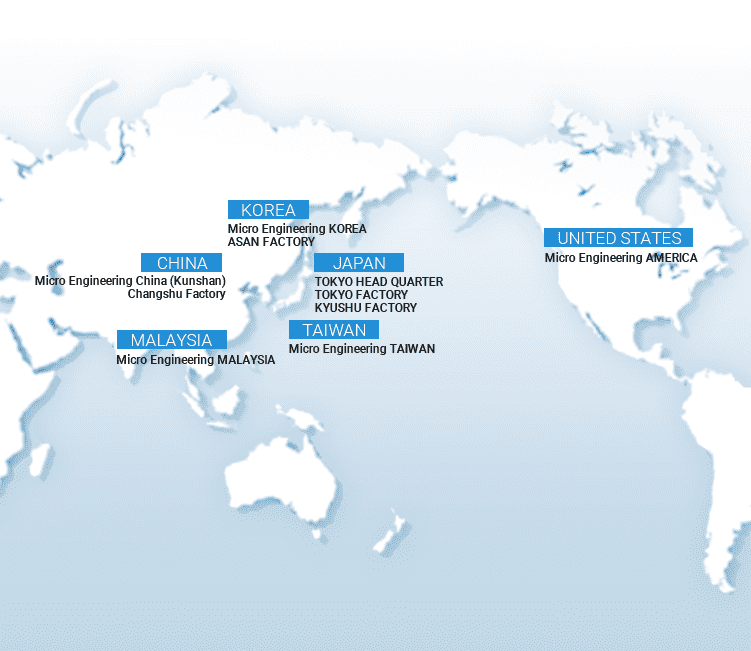

WORLD WIDE NETWORK

Overseas Network Aiming for Global Standards

In addition to Japan, Micro Engineering, Inc. is expanding its overseas bases mainly in growing markets in Asia.

Cooperating with each base to respond to customer requests.

OFFICE

Head Office

〒103-0026

Kabutocho MOC Building 3F, 15-12, Nihonbashi Kabutocho, Chuo-ku, Tokyo

TEL:03(3668)8131

FAX:03(3668)8130